- Schedule. Mon - Sat 10.00 - 18.00

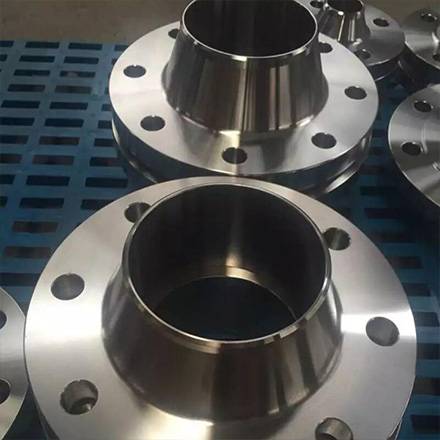

Stainless Steel Weld Neck Flanges Manufacturers and Exporters

MANUFACTURER/EXPORTER OF HIGH QUALITY WELD NECK FORGED FLANGES

Satin Steels Solutions specializes in manufacturing high-quality weld neck flanges that meet ASME, ANSI, and DIN standards in India. We offer immediate delivery programs for standard sizes of carbon steel and stainless steel weld neck flanges. Weld neck pipe flanges are attached to pipes by welding the pipe to the neck of the flange, which transfers stress from the weld neck to the pipe, reducing high stress concentration at the base of the flange hub. These flanges are typically used in high-pressure applications and in environments with extreme temperatures. The inside diameter of a weld neck pipe flange is precisely machined to match the pipe’s inside diameter.

CARBON, ALLOY, STAINLESS STEEL WELD NECK FLANGES

We manufacture weld neck pipe flanges at our facility, supplying them to companies across various industries, including shipbuilding, power generation, petrochemical plants, oil refineries, wastewater treatment plants, paper mills, pharmaceutical plants, and turnkey projects, among others. Our products are widely exported to countries and regions such as the United States, Europe, Russia, Turkey, Malaysia, the UAE, Saudi Arabia, Iran, Brazil, Chile, Mexico, South Africa, Jordan, Tunisia, Vietnam, Indonesia, Thailand, Singapore, Colombia, and Sri Lanka.

Welding Neck Flange, WN Forged Flanges, Weld Neck Flanges Production Range:

| Size: | 1/2″ (15 NB) to 48″ (1200NB) |

| Standards: | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Pressure Ratings: | Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Carbon Steel Weld Neck Flanges: | ASTM A105/A105N, A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, A694 F42, F46, F48, F50, F52, F56, F60, F65, F70, A516.60, 65, 70 (Spectacle Blind Flange, Spacer Ring/Spade Flange), Steel RST37.2, C22.8 |

| Stainless Steel Weld Neck Flanges: | ASTM A182 F202, F304/304L/304H, F316/316L, F316H, F316TI, F310, F321, F904L |

| Alloy Steel Weld Neck Flanges: | ASTM A182 F1, F5, F9, F11, F22, F91 |

| Special Alloy Weld Neck Flanges: | Duplex, Super Duplex, Nickel Alloys |

| Flange Face Type: | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Coating/Surface Treatment: | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Value Added Services: | CNC Machining, Customised Flanges |

Technical Information – Specifications, Dimensions Weld Neck Flanges

» ANSI/ASME B16.5 Welding Neck Flange 150lb

» ANSI/ASME B16.5 Welding Neck Flange 300lb

» ANSI/ASME B16.5 Welding Neck Flange 400lb

» ANSI/ASME B16.5 Welding Neck Flange 600lb

» ANSI/ASME B16.5 Welding Neck Flange 900lb

» ANSI/ASME B16.5 Welding Neck Flange 1500lb

» ANSI/ASME B16.5 Welding Neck Flange 2500lb

» ANSI/ASME B16.47 Series B Weld Neck Flange 75lb

» ANSI/ASME B16.47 Series B Weld Neck Flange 150lb

» ANSI/ASME B16.47 Series B Weld Neck Flange 300lb

» ANSI/ASME B16.47 Series B Weld Neck Flange 600lb

» ANSI/ASME B16.47 Series B Weld Neck Flange 400lb

» ANSI/ASME B16.47 Series B Weld Neck Flange 900lb

» ANSI/ASME B16.47 Series A (MSS SP44) Weld Neck Flange 150lb

» ANSI/ASME B16.47 Series A (MSS SP44) Weld Neck Flange 300lb

» ANSI/ASME B16.47 Series A (MSS SP44) Weld Neck Flange 400lb

» ANSI/ASME B16.47 Series A (MSS SP44) Weld Neck Flange 600lb

» ANSI/ASME B16.47 Series A (MSS SP44) Weld Neck Flange 900lb

Types of Flanges

Stainless Steel Weld Neck Flanges SS 304 Weld Neck Flanges

Alloy Steel F5 Weld Neck Flanges Alloy Steel Weld Neck Flanges

High Nickel Alloy Weld Neck Flanges Nickel Weld Neck Flanges

What is WNRF Flanges ?

A Weld Neck Raised Face (WNRF) Flange, commonly referred to as a Weld Neck Flange, is a type of flange intended for welding onto a pipe. It features a long, tapered neck that gradually transitions to match the pipe’s diameter. This design makes the WNRF Flange particularly suitable for high-pressure and high-temperature applications.

Materials Used in Manufacturing:

WNRF Flanges can be made from various materials, such as carbon steel, stainless steel, and alloy steel. The selection of material depends on the specific requirements of the project, including the application’s temperature and pressure conditions.

Advantages of Using WNRF Flanges

Using WNRF Flanges in your project offers several advantages. Their design is ideal for high-pressure and high-temperature applications, ensuring safety and reliability. The welding process used to attach the flange to the pipe creates a strong and permanent connection. Furthermore, WNRF Flanges are versatile and suitable for various applications, including oil and gas, chemical processing, and power generation.

WNRF Flange Dimensions and Standards: WNRF Flanges are available in various sizes and dimensions, making it essential to select the correct size for your project. They are manufactured according to several standards, including ASME/ANSI, API, and DIN. Our team can assist you in choosing the appropriate size and standard for your needs.

Proper installation of WNRF Flanges is crucial for the safety and reliability of your project. Our team can provide guidance on correct installation procedures to ensure your project’s success.

These flanges are bored to match the inside diameter of the fitting or mating pipe, preventing flow restriction, turbulence, and reducing erosion at the joints. They offer excellent distribution via a tapered hub and can be easily radiographed for flaw detection. Additionally, these flanges can be easily welded to fittings or pipes with a V weld or single full penetration weld.

Weld Neck Flanges Application Industries

- Petrochemical Industry

- Chemical Industry

- Oil and Gas Industry

- Pulp & Paper Indusry

- Power Plant Industry

- Food Processing Industry

- Pharmaceuticals Industry

- Energy Industry

- Aerospace Industry

Stock Size Range and Specifications For Weld Neck Flanges

Specification : ASTM A182 / B564 / A105 / A350 / A694 / B381.

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2″ (15 NB) to 48″ (1200NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673

JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges : BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Stainless Steel Ring Type Joint Flanges : 304, 304L, 304H, 310s, 316, 316L, 316H, 316Ti, 317/317L, 321/321H, 347/347H, 904L, 446.

Duplex Steel Ring Type Joint Flanges : S31803 F51, S32205 F60.

Super Duplex Steel Ring Type Joint Flanges : S32750, S32760.

Carbon Steel Ring Type Joint Flanges : A105, LF2, IS 2062, F42, F46, F52, F60, F65, F70.

Alloy Steel Ring Type Joint Flanges : F1, F5, F9, F11, F12, F22, F91.

High Nickel Alloy : 200, 201, 400, K500, 600, 601, 625, 718, 800, 825, C22, C276, B2, X.

Alloy 20 Ring Type Joint Flanges : Alloy 20.

Randomised words which don’t look even slightly believable. If you are going passage of you need sure there anything make a type specimen book. It has survived not only five centuries.

Randomised words which don’t look even slightly believable. If you are going passage of you need sure there anything make a type specimen book. It has survived not only five centuries.

We are always ready to help you and answer your questions